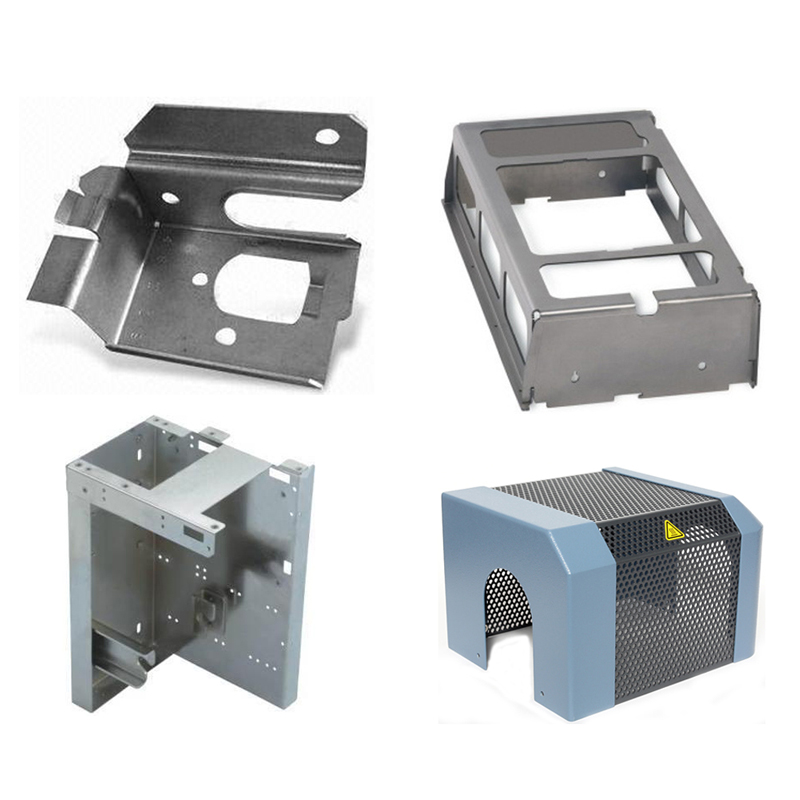

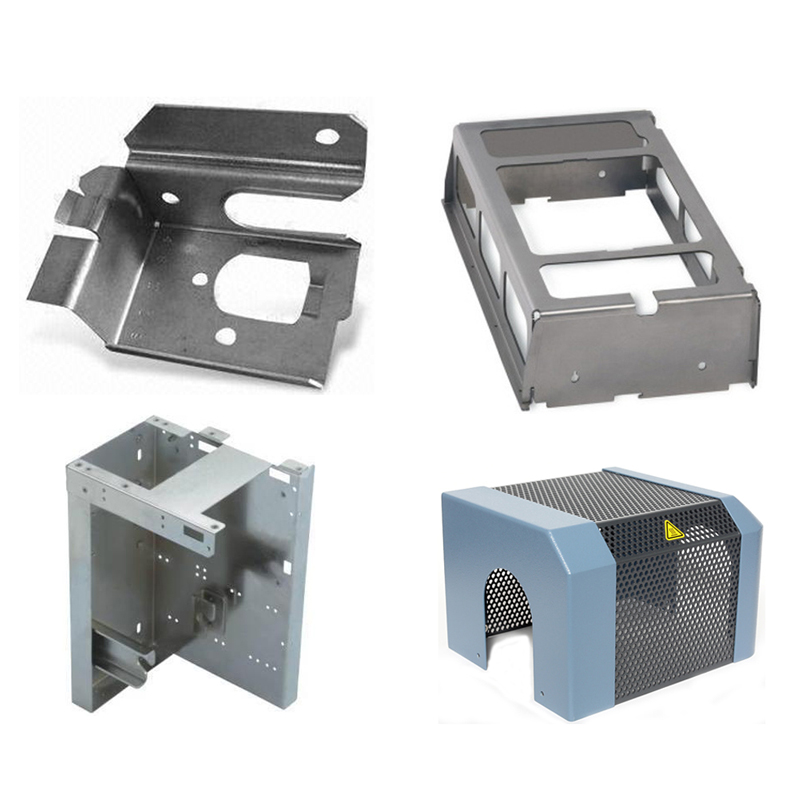

Ricambi auto aftermarket di ricambio a basso costo all'ingrosso

ricambi auto, vendita all'ingrosso di ricambi auto, ricambi auto aftermarket, ricambi auto, pezzi di ricambio per auto. Personalizzazione rapida su ricambi auto aftermarket, basta inviarci campioni originali o disegni.